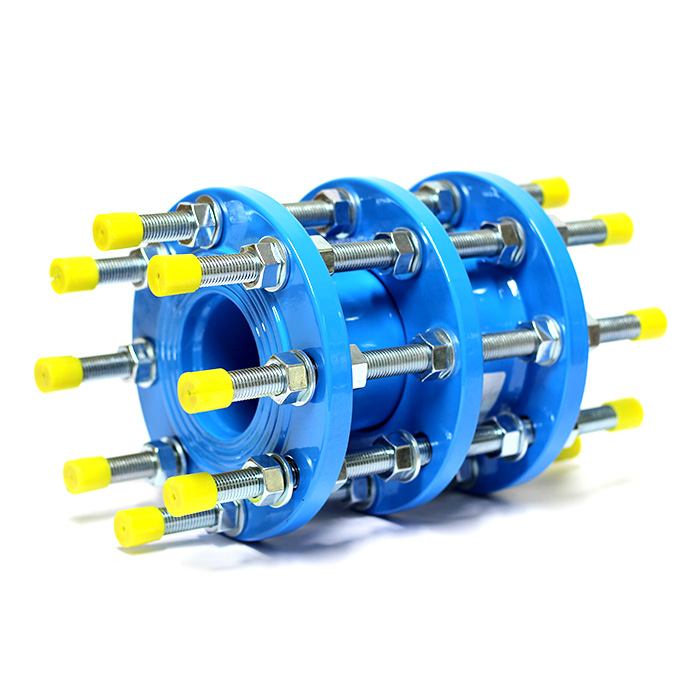

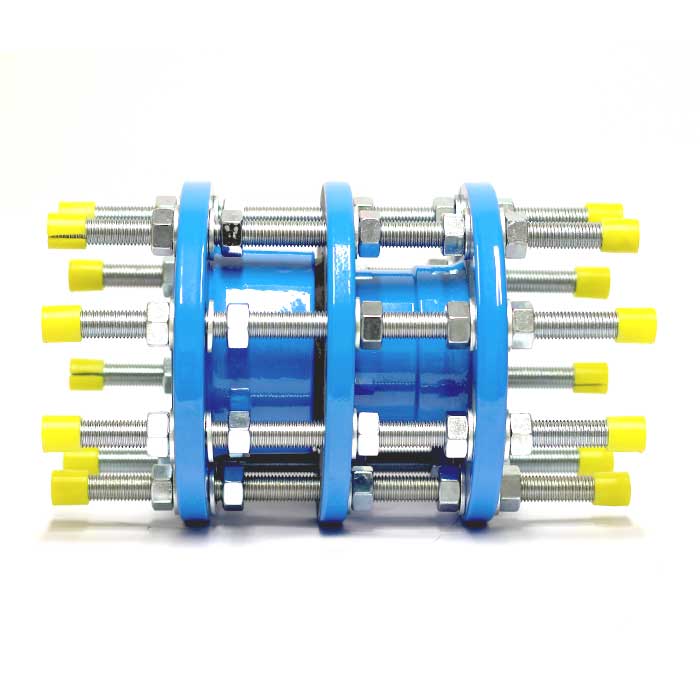

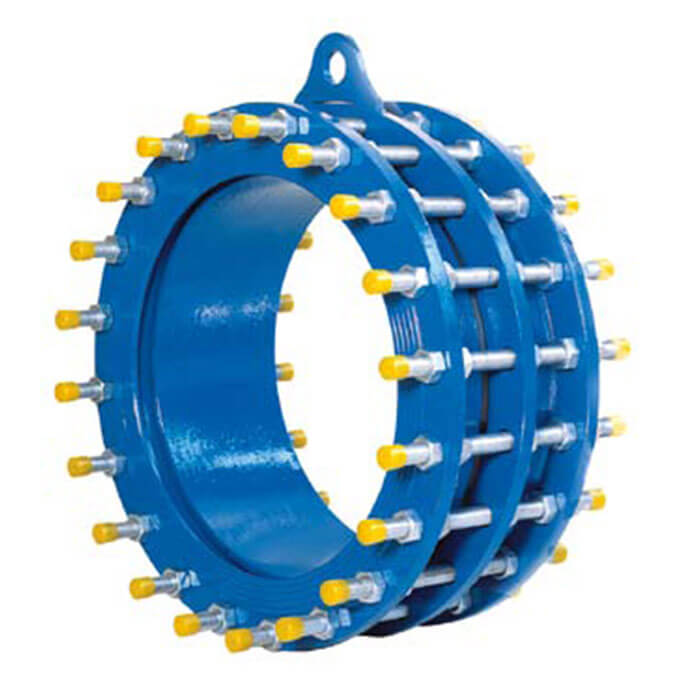

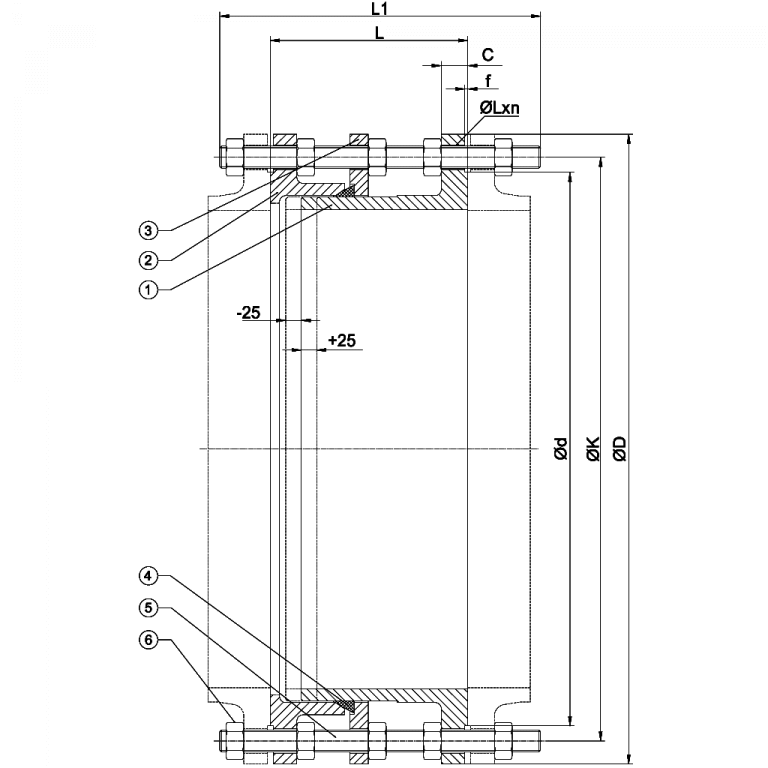

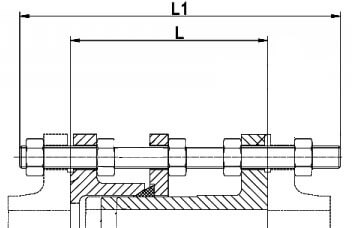

Double flanged fitting, which allows longituduinal adjustmanets in flanged pipe systems.

Easy assembly and disassembly of flange-fittings.

Continuous threaded bars, therefore, no additional mounting screws necessary.

Lenght adjustment: face to face L (see table) +/- 25mm

Flange connection dimensions in accordance with EN 1092-2 - PN10, PN16, PN25 (PN40 on request)

Material / Technical Features

Flanges - ductile iron/steel, epoxy powder coated

Retaining flange - steel, epoxy powder coated

Sealing Ring - elastomer

Threaded Bar - galvanised steel, epoxy powder coated

Bolts - galvanised steel

Hawle Dismantling Joints

Hawle Dismantling Joint Technical Specifications

Dismantling Technical Specifications

| Adjustment Range | Diameter | Pressure [bar] | Flange type | Length [mm] | Weight [kg] |

|---|---|---|---|---|---|

| Length: 155 - 205 | DN 50 | 16 | 10/16 | 180 | 11,00 |

| Length: 155 - 205 | DN 65 | 16 | 10/16 | 180 | 13,00 |

| Length: 175 - 225 | DN 80 | 16 | 10/16 | 200 | 17,00 |

| Length: 175 - 225 | DN 100 | 16 | 10/16 | 200 | 20,00 |

| Length: 175 - 225 | DN 125 | 16 | 10/16 | 200 | 24,00 |

| Length: 175 - 225 | DN 150 | 16 | 10/16 | 200 | 30,00 |

| Length: 195 - 245 | DN 200 | 10 | 10 | 220 | 42,00 |

| Length: 195 - 245 | DN 200 | 16 | 16 | 220 | 45,00 |

| Length: 195 - 245 | DN 250 | 10 | 10 | 220 | 62,00 |

| Length: 195 - 245 | DN 250 | 16 | 16 | 220 | 66,00 |

| Length: 195 - 245 | DN 300 | 10 | 10 | 220 | 67,00 |

| Length: 195 - 245 | DN 300 | 16 | 16 | 220 | 84,00 |

| Length: 235 - 285 | DN 400 | 10 | 10 | 260 | 105,00 |

| Length: 235 - 285 | DN 400 | 16 | 16 | 260 | 142,00 |

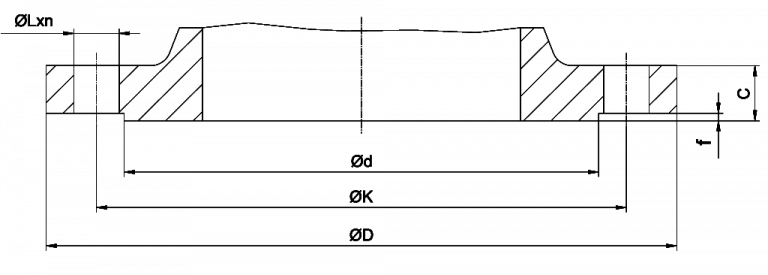

Technical Specifications - Pressure Rating PN10

| DN (mm) | f | ØD | ØK | Ød | C | ØLxn |

|---|---|---|---|---|---|---|

| 50 | 3 | 165 | 125 | 99 | 19 | 19×4 |

| 65 | 3 | 185 | 145 | 118 | 19 | 19×4 |

| 80 | 3 | 200 | 160 | 132 | 19 | 19×8 |

| 100 | 3 | 220 | 180 | 156 | 19 | 19×8 |

| 125 | 3 | 250 | 210 | 184 | 19 | 19×8 |

| 150 | 3 | 285 | 240 | 211 | 19 | 23×8 |

| 200 | 3 | 340 | 295 | 266 | 20 | 23×8 |

| 250 | 3 | 405 | 350 | 319 | 22 | 23×12 |

| 300 | 4 | 460 | 400 | 370 | 24.5 | 23×12 |

| 350 | 4 | 505 | 460 | 429 | 24.5 | 23×16 |

| 400 | 4 | 565 | 515 | 480 | 24.5 | 28×16 |

| 450 | 4 | 640 | 565 | 530 | 30 | 28×20 |

| 500 | 4 | 670 | 620 | 582 | 26.5 | 28×20 |

| 600 | 5 | 780 | 725 | 682 | 30 | 31×20 |

| 700 | 5 | 895 | 840 | 794 | 32.5 | 31×24 |

| 800 | 5 | 1015 | 950 | 901 | 35 | 34×24 |

| 900 | 5 | 1115 | 1050 | 1001 | 37.5 | 34×28 |

| 1000 | 5 | 1230 | 1160 | 1112 | 40 | 37×28 |

| 1100 | 5 | 1355 | 1270 | 1218 | 53.5 | 37×32 |

| 1200 | 5 | 1455 | 1380 | 1328 | 45 | 41×32 |

| 1300 | 5 | 1585 | 1490 | 1440 | 59 | 42×32 |

| 1400 | 5 | 1675 | 1590 | 1530 | 46 | 44×36 |

| 1500 | 5 | 1820 | 1700 | 1640 | 62.5 | 44×36 |

| 1600 | 5 | 1915 | 1820 | 1750 | 49 | 50×40 |

| 1800 | 5 | 2130 | 2020 | 1950 | 70 | 50×44 |

| 2000 | 5 | 2345 | 2230 | 2150 | 75 | 50×48 |

| 2200 | 5 | 2550 | 2440 | 2370 | 65 | 57×52 |

| 2400 | 6 | 2760 | 2650 | 2570 | 65 | 56×56 |

| 2500 | 6 | 2860 | 2750 | 2670 | 65 | 56×56 |

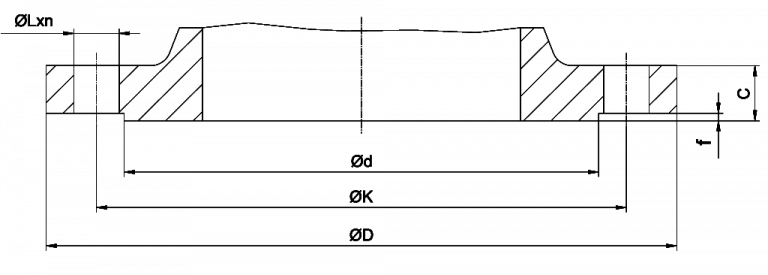

Technical Specifications - Pressure Rating PN16

| DN (mm) | f | ØD | ØK | Ød | C | ØLxn |

|---|---|---|---|---|---|---|

| 50 | 3 | 165 | 125 | 99 | 19 | 19×4 |

| 65 | 3 | 185 | 145 | 118 | 19 | 19×4 |

| 80 | 3 | 200 | 160 | 132 | 19 | 19×8 |

| 100 | 3 | 220 | 180 | 156 | 19 | 19×8 |

| 125 | 3 | 250 | 210 | 184 | 19 | 19×8 |

| 150 | 3 | 285 | 240 | 211 | 19 | 23×8 |

| 200 | 3 | 340 | 295 | 266 | 20 | 23×12 |

| 250 | 3 | 405 | 355 | 319 | 22 | 28×12 |

| 300 | 4 | 460 | 410 | 370 | 24.5 | 28×12 |

| 350 | 4 | 520 | 470 | 429 | 26.5 | 28×16 |

| 400 | 4 | 580 | 525 | 480 | 28 | 31×16 |

| 450 | 4 | 640 | 585 | 548 | 30 | 31×20 |

| 500 | 4 | 715 | 650 | 609 | 31.5 | 34×20 |

| 600 | 5 | 840 | 770 | 720 | 36 | 37×20 |

| 700 | 5 | 910 | 840 | 794 | 39.5 | 37×24 |

| 800 | 5 | 1025 | 950 | 901 | 43 | 41×24 |

| 900 | 5 | 1125 | 1050 | 1001 | 46.5 | 41×28 |

| 1000 | 5 | 1255 | 1170 | 1112 | 50 | 44×28 |

| 1100 | 5 | 1355 | 1270 | 1218 | 53.5 | 44×32 |

| 1200 | 5 | 1485 | 1390 | 1328 | 57 | 50×32 |

| 1300 | 5 | 1585 | 1490 | 1432 | 59 | 48×32 |

| 1400 | 5 | 1685 | 1590 | 1530 | 60 | 50×36 |

| 1500 | 5 | 1820 | 1710 | 1640 | 62.5 | 57×36 |

| 1600 | 5 | 1930 | 1820 | 1750 | 65 | 57×40 |

| 1800 | 5 | 2130 | 2020 | 1950 | 70 | 57×44 |

| 2000 | 5 | 2345 | 2230 | 2150 | 75 | 62×48 |

| 2200 | 5 | 2555 | 2440 | 2360 | 80 | 62×52 |

| 2400 | 6 | |||||

| 2500 | 6 |

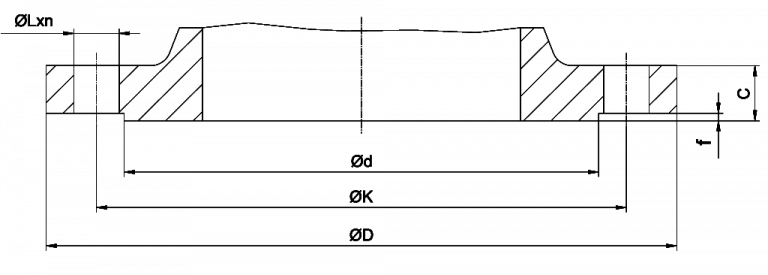

Technical Specifications - Pressure Rating PN25

| DN (mm) | f | ØD | ØK | Ød | C | ØLxn |

|---|---|---|---|---|---|---|

| 50 | 3 | 165 | 125 | 99 | 19 | 19×4 |

| 65 | 3 | 185 | 145 | 118 | 19 | 19×4 |

| 80 | 3 | 200 | 160 | 132 | 19 | 19×4 |

| 100 | 3 | 235 | 190 | 156 | 19 | 23×8 |

| 125 | 3 | 270 | 220 | 184 | 19 | 28×8 |

| 150 | 3 | 300 | 250 | 211 | 20 | 28×8 |

| 200 | 3 | 360 | 310 | 274 | 22 | 28×12 |

| 250 | 3 | 450 | 370 | 330 | 34.5 | 31×12 |

| 300 | 4 | 485 | 430 | 389 | 27.5 | 31×16 |

| 350 | 4 | 555 | 490 | 448 | 30 | 34×16 |

| 400 | 4 | 620 | 550 | 503 | 32 | 37×16 |

| 450 | 4 | 670 | 600 | 548 | 34.5 | 37×20 |

| 500 | 4 | 730 | 660 | 609 | 36.5 | 37×20 |

| 600 | 5 | 845 | 770 | 720 | 42 | 41×20 |

| 700 | 5 | 960 | 875 | 820 | 46.5 | 44×24 |

| 800 | 5 | 1085 | 990 | 928 | 51 | 50×24 |

| 900 | 5 | 1185 | 1090 | 1028 | 55.5 | 50×28 |

| 1000 | 5 | 1320 | 1210 | 1140 | 60 | 57×28 |

| 1100 | 5 | 1420 | 1310 | 1240 | 64.5 | 57×32 |

| 1200 | 5 | 1530 | 1420 | 1350 | 69 | 57×32 |

| 1300 | 5 | |||||

| 1400 | 5 | 1755 | 1640 | 1560 | 74 | 62×36 |

| 1500 | 5 | |||||

| 1600 | 5 | 1975 | 1860 | 1780 | 81 | 62×40 |

| 1800 | 5 | 2195 | 2070 | 1985 | 88 | 70×44 |

| 2000 | 5 | 2425 | 2300 | 2210 | 95 | 70×48 |

| 2200 | 5 | |||||

| 2400 | 6 | |||||

| 2500 | 6 |

Material Properties

| Part No | Description | Material |

|---|---|---|

|

1 |

Flanged pipe – long |

Ductile cast iron EN-GJS-400-15 |

|

2 |

Flanged pipe – short |

Ductile cast iron EN-GJS-400-15 |

|

3 |

Retaining flange |

Steel S235JR |

|

4 |

Sealing ring |

EPDM |

|

5 |

Stud bolt |

Steel-Galvanized |

|

6 |

Nut |

Steel-Galvanized |

Technical Information

| DN | PN 10 | PN 16 | PN 25 | ||||||

| L | L1 | WEIGHT Kg |

L | L1 | WEIGHT Kg |

L | L1 | WEIGHT (KG) |

|

| 100 | 200 | 330 | 20 | 200 | 330 | 20 | 220 | 340 | 32 |

| 125 | 200 | 330 | 24 | 200 | 330 | 24 | 220 | 370 | 43 |

| 150 | 200 | 320 | 30 | 200 | 320 | 30 | 230 | 370 | 52 |

| 200 | 220 | 330 | 42 | 220 | 330 | 45 | 230 | 370 | 76 |

| 250 | 220 | 360 | 62 | 230 | 370 | 66 | 250 | 410 | 108 |

| 300 | 220 | 360 | 67 | 250 | 410 | 84 | 250 | 410 | 129 |

| 350 | 230 | 360 | 85 | 260 | 410 | 107 | 270 | 480 | 196 |

| 400 | 230 | 370 | 105 | 270 | 430 | 142 | 280 | 500 | 212 |

| 450 | 250 | 390 | 131 | 270 | 430 | 177 | 280 | 480 | 281 |

| 500 | 260 | 390 | 155 | 280 | 440 | 200 | 300 | 500 | 290 |

| 600 | 260 | 410 | 225 | 300 | 500 | 305 | 320 | 520 | 389 |

| 700 | 260 | 410 | 300 | 300 | 500 | 321 | 340 | 530 | 505 |

| 800 | 290 | 460 | 361 | 320 | 520 | 469 | 360 | 600 | 690 |

| 900 | 290 | 460 | 400 | 320 | 520 | 535 | 380 | 600 | 920 |

| 1000 | 290 | 500 | 516 | 340 | 560 | 698 | 400 | 650 | 1257 |

| 1100 | 300 | 480 | 830 | 340 | 560 | 830 | |||

| 1200 | 320 | 520 | 895 | 360 | 600 | 1070 | 450 | 720 | 1870 |

| 1300 | 370 | 630 | 1172 | 370 | 630 | 1172 | |||

| 1400 | 360 | 560 | 1194 | 380 | 630 | 1270 | |||

| 1500 | 380 | 590 | 1560 | 380 | 610 | 1560 | |||

| 1600 | 390 | 600 | 1436 | 400 | 700 | 1705 | |||

| 1800 | 450 | 750 | 1880 | ||||||

| 2000 | 450 | 750 | 2206 | ||||||

| 2200 | 450 | 750 | 2800 | ||||||

| 2400 | 450 | 750 | 3400 | ||||||

| 2500 | 450 | 750 | 3620 | ||||||