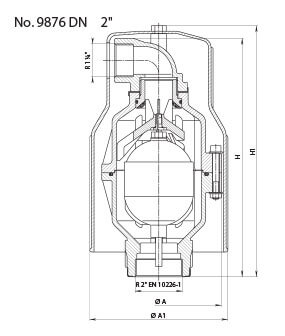

Hawle Air Release Valves, No. 9876 and No. 9842

No. 9876 Design features:

Automatic, dynamic air release valve

PE shield for UV protection

The internal thread inlet is reinforced with a stainless steel ring

Connection variants: Internal thread or flange

Insect protective grid (2" valve)

Installation: upright, preferably at the highest point in the pipeline together with isolating valves

Air valve for releasing air only: on request (minimum pressure of 0,3 bar needed)

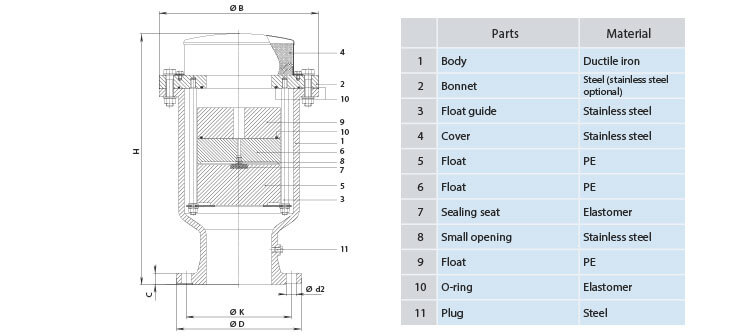

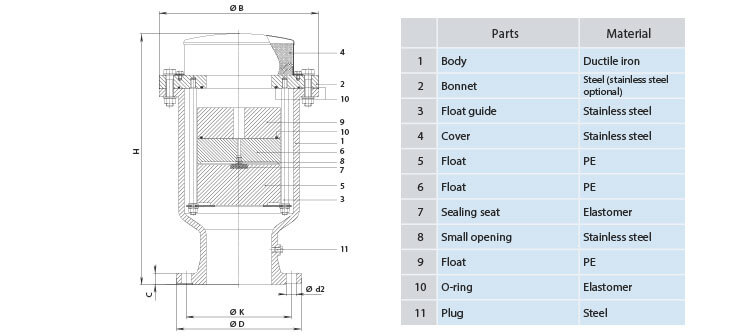

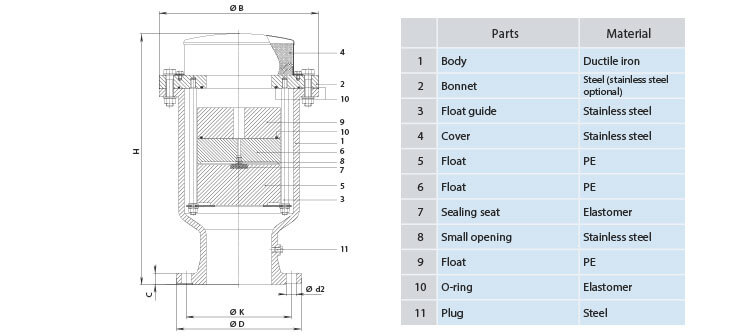

No. 9842 Design features

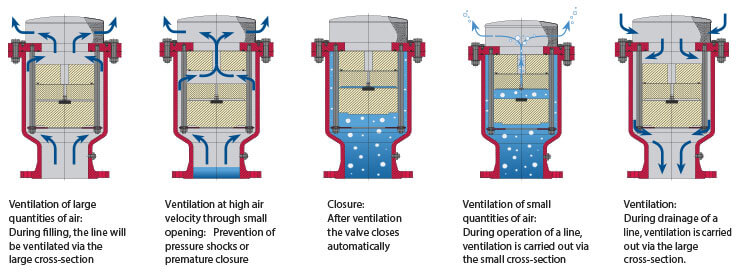

Automatic 3-way air release valve with cylindrical floats

Ventilation outlet in nominal size (large opening cross-section according to the flange size)

Flange pursuant to EN 1092-2 (DN 50 can also be shipped with threaded connection 2")

Efficient, high performance ventilation protects pipeline from vacuum related damages

High velocity air discharge prevents premature closure, thus safeguarding optimum ventilation during filling process of pipe lines or containers

2-level ventilation system provides effective protection against pressure shocks during high ventilation speeds through a small opening

Continuously reliable ventilation of air inlets under normal operating conditions

Compact construction, low volume and weight

Robust and reliable technology

Hawle Air Release Valves Range

Automatic, dynamic air release valve

PE shield for UV protection

The internal thread inlet is reinforced with a stainless steel ring

Connection variants: Internal thread or flange

Insect protective grid (2" valve)

Installation: upright, preferably at the highest point in the pipeline together with isolating valves

Air valve for releasing air only: on request (minimum pressure of 0,3 bar needed)

| DN |

MOP (PN) |

Working pressure bar |

Size of the opening |

Ø A |

Ø A1 |

H |

H1 |

Weight |

| 2" |

6 |

0,1 - 6 |

900/2 mm2 |

160 |

175 |

305 |

320 |

2,90 |

| 16 |

1 - 16 |

3,40 |

Automatic 3-way air release valve with cylindrical floats

Ventilation outlet in nominal size (large opening cross-section according to the flange size)

Flange pursuant to EN 1092-2 (DN 50 can also be shipped with threaded connection 2")

Efficient, high performance ventilation protects pipeline from vacuum related damages

High velocity air discharge prevents premature closure, thus safeguarding optimum ventilation during filling process of pipe lines or containers

2-level ventilation system provides effective protection against pressure shocks during high ventilation speeds through a small opening

Continuously reliable ventilation of air inlets under normal operating conditions

Compact construction, low volume and weight

Robust and reliable technology

| DN |

MOP (PN) |

Ø D |

Ø K |

C |

Bolts |

Ø B |

H |

Weight |

| Quantity |

Ø d2 |

| 50 |

10/16 |

165 |

125 |

19 |

4 |

19 |

200 |

355 |

20 |

| 80 |

200 |

160 |

19 |

8 |

19 |

240 |

420 |

26 |

| 100 |

220 |

180 |

19 |

8 |

19 |

255 |

420 |

28 |

| 150 |

285 |

240 |

19 |

8 |

23 |

365 |

580 |

90 |

| 200 |

10 |

340 |

295 |

20 |

8 |

23 |

410 |

630 |

98 |

| 200 |

16 |

340 |

295 |

20 |

12 |

23 |

410 |

630 |

98 |

| 250 |

10 |

405 |

355 |

22 |

12 |

23 |

540 |

820 |

160 |

| 250 |

16 |

405 |

355 |

22 |

12 |

28 |

540 |

820 |

160 |

| 300 |

16 |

460 |

410 |

24,5 |

12 |

28 |

650 |

927 |

180 |

| DN |

MOP (PN) |

Ø D |

Ø K |

C |

Bolts |

Ø B |

H |

Weight |

| Quantity |

Ø d2 |

| 50 |

25 |

165 |

125 |

19 |

4 |

19 |

200 |

355 |

22 |

| 80 |

200 |

160 |

19 |

8 |

19 |

240 |

420 |

28 |

| 100 |

235 |

190 |

19 |

8 |

23 |

255 |

420 |

30 |

| 150 |

300 |

250 |

20 |

8 |

28 |

365 |

580 |

95 |

| DN |

MOP (PN) |

Ø D |

Ø K |

C |

Bolts |

Ø B |

H |

Weight |

| Quantity |

Ø d2 |

| 100 |

40 |

235 |

190 |

19 |

8 |

23 |

255 |

420 |

30 |