We all know the problems that may arise after dismantling an old valve or a

cross connection as a consequence of decreasing tension and subsiding of the

pipeline.

It is often impossible to close the gap by means of standard fittings.

The perfect answer to this problem is the latest innovation developed by Hawle – the Hawle VARIO

Product BENEFITS:

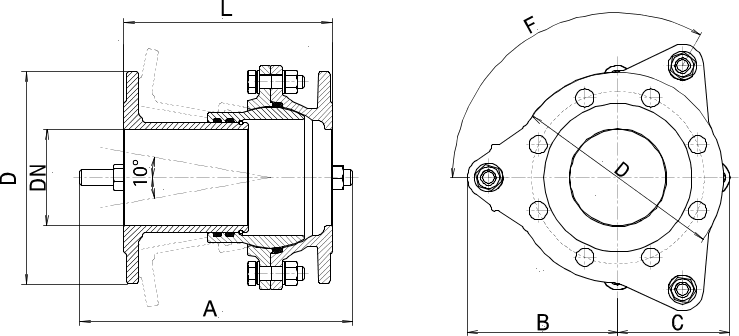

The Hawle VARIO is a flanged telescopic fitting with integral universal joint that permits bending to all sides up to 10 degrees. DESIGN FEATURES:

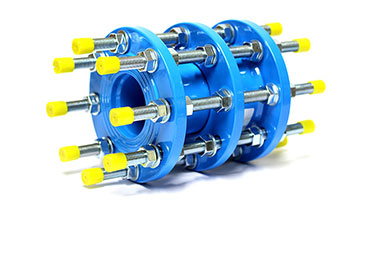

All components of the Hawle VARIO are 100% fluidized bed epoxy powder coated all over and made of corrosion-resistant materials. The Hawle VARIO is suitable for potable water up to a max. operating pressure of 16 bar. TENSION LOCK:

By means of the tension lock assembly the Hawle VARIO should be fixed in the installed position. All HAWLE VARIO fittings are delivered with a tension lock assembly. All castings are made of EN-GJS-400 (GGG 40), EWS epoxy powder coated acc. to DIN 30677-T2 inside and outside, subject to DIN 3476 as well as all quality and testing specifications acc. to the RAL Mark of Quality 662 (GSK - The Quality Association for Heavy Duty Corrosion Protection).Locking ring, through bolts and washers of A2 Stainless Steel

O-rings: EPDM approved standard for food handling

The Hawle VARIO is a flanged telescopic fitting with integral universal joint that permits bending to all sides up to 10 degrees. DESIGN FEATURES:

All components of the Hawle VARIO are 100% fluidized bed epoxy powder coated all over and made of corrosion-resistant materials. The Hawle VARIO is suitable for potable water up to a max. operating pressure of 16 bar. TENSION LOCK:

By means of the tension lock assembly the Hawle VARIO should be fixed in the installed position. All HAWLE VARIO fittings are delivered with a tension lock assembly. All castings are made of EN-GJS-400 (GGG 40), EWS epoxy powder coated acc. to DIN 30677-T2 inside and outside, subject to DIN 3476 as well as all quality and testing specifications acc. to the RAL Mark of Quality 662 (GSK - The Quality Association for Heavy Duty Corrosion Protection).