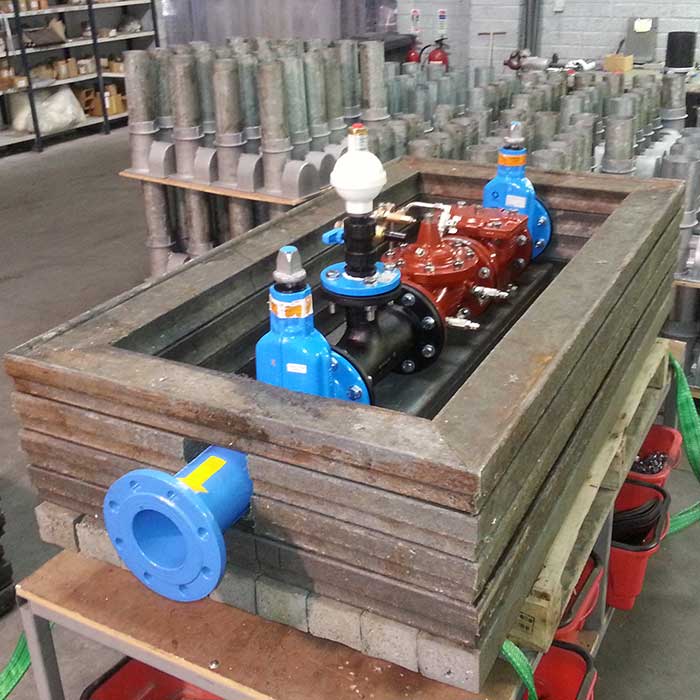

IPL group offer customers the benefits of product standardisation and

off-site construction with the introduction of pre-assembled chambers

for quick and easy on site installation.

For some chamber installations the last place to assemble, build and test a chamber

is in a hole in the ground. Sites are typically fraught with problems and challenges

both for clients and crew carrying out the assembly. It is recognised that chamber

assembly is a demanding and skilled process requiring planning and resources. The

mix of site conditions, tools and equipment available together with an element of

uncertainty can often see installations suffer from reduced quality, delays and

additional costs.

The use of pre-assembled chambers has shown to be very effective in terms of

quality, time, cost and worker safety with overall improved project performance and

customer satisfaction.

The IPL group sub-assembly process — the integration of design and construction on

the factory floor — gives the customer an opportunity to adopt the best construction

practices available where experienced IPL group technicians routinely complete

chambers in a clean quality controlled manufacturing environment.