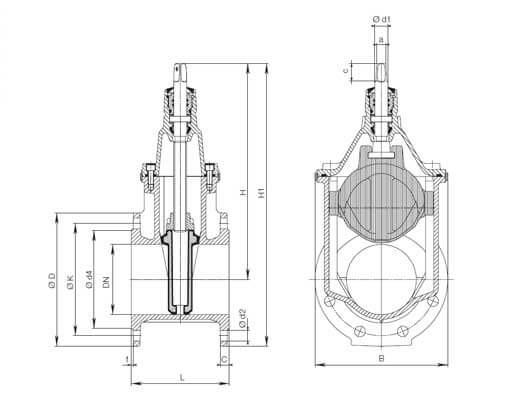

DN 50 - 200

Resilient seated gate valve with smooth straight-through bore

Flanges sized in accordance with EN 1092-2, drilled according to

EN 1092-2 | PN 10 standard (4000E2, 4700E2);

EN 1092-2 | PN 25 (4010E2, 4710E2)

EN 1092-2 | PN 16 from DN 200 (4000E2, 4700E2)

Please specify on order - other standards on request

Suitable for cleaning with a cleaning pig

One extension spindle for several dimensions

Suitable for operation by automatic actuators

Easy refitting for position indicator and automatic actuators on the standard bonnet

Duplex stainless steel spindle

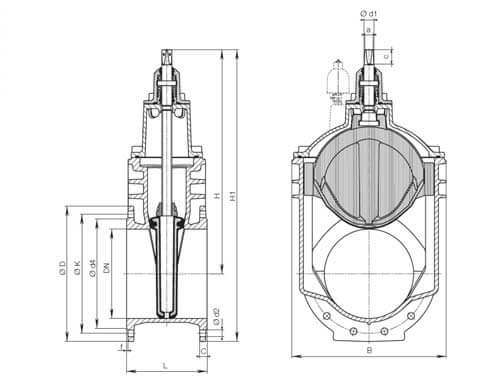

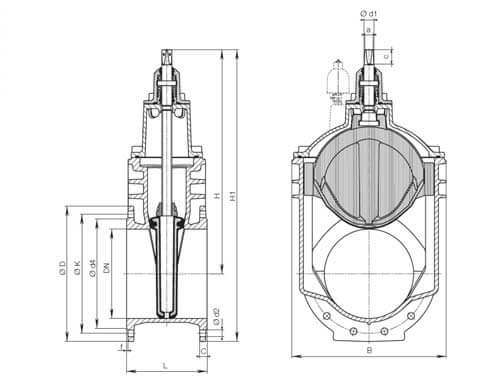

DN 250 - 600

Resilient seated gate valve with smooth straight-through bore

Flanges sized in accordance with EN 1092-2, drilled according to

EN 1092-2 | PN 10 standard (4000E2, 4700E2);

EN 1092-2 | PN 25 (4710E2)

EN 1092-2 | PN 16 from DN 200 (4000E2, 4700E2)

Please specify on order - other standards on request

Suitable for cleaning with a cleaning pig

Suitable for operation by automatic actuators

O-rings replaceable under pressure

Ball bearings in the spindle seating minimizes closing forces

Easy to actuate without bypass and without power boost - even for 16 bar differential pressure

For the assembling of a position indicator it is necessary to remove the centering flange and mount the adapter for position indicator

For the assembling of an electric actuator it is necessary to remove the centering flange and mount the adapter for electric actuator and a coated spindle (DN 250 - DN 400)

Hawle E2 DN 50 - 600 Technical Specifications

| DN |

PN |

Flange |

Bolts |

Spindle |

Valve |

Weight (kg) |

| ØD |

C |

ØK |

Ød4 |

F |

Qty |

Thread |

Ød2 |

A |

C |

Ød1 |

H |

H1 |

L Short |

L Long |

B |

Short |

Long |

| 50 |

10 |

165 |

19 |

125 |

98 |

3 |

4 |

M 16 |

19 |

14.8 |

30 |

22 |

260 |

342 |

150 |

250 |

143 |

11.0 |

12.0 |

| 16 |

| 25 |

| 65 |

10 |

185 |

19 |

145 |

118 |

3 |

4 |

M 16 |

19 |

17.3 |

35 |

25 |

328 |

420 |

170 |

270 |

180 |

17.0 |

18.0 |

| 16 |

| 25 |

8 |

| 80 |

10 |

200 |

19 |

160 |

133 |

3 |

8 |

M 16 |

19 |

17.3 |

35 |

25 |

336 |

436 |

180 |

280 |

180 |

18.5 |

20.5 |

| 16 |

| 25 |

| 100 |

10 |

220 |

19 |

180 |

153 |

3 |

8 |

M 16 |

19 |

19.3 |

38 |

25 |

373 |

483 |

190 |

300 |

213 |

24.5 |

27.5 |

| 16 |

| 25 |

235 |

190 |

M 20 |

23 |

480 |

| 125 |

10 |

250 |

19 |

210 |

183 |

3 |

8 |

M 16 |

19 |

19.3 |

38 |

28 |

450 |

575 |

200 |

325 |

285 |

35.5 |

38.0 |

| 16 |

| 25 |

270 |

220 |

M 24 |

28 |

480 |

35.0 |

| 150 |

10 |

285 |

19 |

240 |

209 |

3 |

8 |

M 20 |

23 |

19.3 |

38 |

28 |

462 |

605 |

210 |

350 |

285 |

40.5 |

46.0 |

| 16 |

| 25 |

300 |

250 |

M 24 |

28 |

49.0 |

| 200 |

10 |

340 |

20 |

295 |

264 |

3 |

8 |

M 20 |

23 |

24.3 |

48 |

32 |

563 |

733 |

230 |

400 |

357 |

64.0 |

72.0 |

| 16 |

12 |

| 25 |

360 |

310 |

12 |

M 24 |

28 |

743 |

81.0 |

| DN |

PN |

Flange |

|

Bolts |

Spindle |

Valve |

Weight (kg) |

| ØD |

C |

ØK |

Ød4 |

F |

Qty |

Thread |

Ød2 |

A |

C |

Ød1 |

H |

H1 |

L Short |

L Long |

BS 5163 |

B |

Short |

Long |

BS 5163 |

| 250 |

10 |

400 |

22 |

350 |

319 |

3 |

12 |

M 20 |

23 |

27.3 |

48 |

34 |

670 |

870 |

250 |

450 |

330 |

432 |

100.0 |

121.0 |

104.0 |

| 16 |

355 |

| 25 |

425 |

24.5 |

370 |

330 |

M 24 |

28 |

883 |

|

136.0 |

|

| 300 |

10 |

455 |

24.5 |

400 |

367 |

4 |

12 |

M 20 |

23 |

27.3 |

48 |

34 |

753 |

981 |

270 |

500 |

356 |

518 |

147.0 |

170.0 |

153.5 |

| 16 |

410 |

M 24 |

28 |

| 25 |

485 |

27.5 |

430 |

389 |

5 |

16 |

M 27 |

31 |

996 |

|

196.0 |

|

| 350 |

10 |

520 |

26.5 |

460 |

427 |

4 |

16 |

M 20 |

23 |

27.3 |

48 |

34 |

838 |

1098 |

290 |

|

|

604 |

205.0 |

|

|

| 16 |

470 |

M 34 |

28 |

|

|

| 400 |

10 |

580 |

28 |

515 |

477 |

4 |

16 |

M 24 |

28 |

32.3 |

55 |

44 |

974 |

1264 |

310 |

600 |

|

687 |

261.0 |

300.0 |

|

| 16 |

525 |

M 27 |

31 |

|

|

| 450* |

10 |

640 |

30 |

565 |

530 |

4 |

20 |

M 24 |

28 |

32.3 |

55 |

44 |

974 |

1310 |

|

650 |

|

800 |

488.0 |

542.0 |

|

| 16 |

585 |

M 27 |

31 |

|

|

| 500* |

10 |

715 |

31.5 |

620 |

582 |

4 |

20 |

M 24 |

28 |

32.3 |

55 |

44 |

974 |

1345 |

|

700 |

|

687 |

|

371.0 |

|

| 16 |

650 |

M 30 |

34 |

|

|

| 500 |

10 |

715 |

31.5 |

620 |

582 |

4 |

20 |

M 24 |

28 |

36.3 |

66 |

50 |

1220 |

1578 |

350 |

700 |

|

800 |

488.0 |

542.0 |

|

| 16 |

650 |

M 30 |

34 |

|

|

| 600 |

10 |

840 |

36 |

725 |

720 |

5 |

20 |

M 27 |

31 |

36.3 |

66 |

50 |

1377 |

1797 |

390 |

800 |

|

944 |

720.0 |

789.0 |

|

| 16 |

770 |

M 33 |

37 |

|

|

* Body: DN 400 - Flange connection: DN450 or 500